Safety and Storage

Safety and Storage

Finally, the environmental impact of natural gas distribution is minimized through proper pressure regulation. By ensuring efficient transportation and minimizing losses due to leaks or bursts, PRS stations help promote the broader adoption of natural gas as a cleaner fossil fuel alternative.

What Are Electric Auxiliary Heaters?

Despite its many advantages, natural gas is not without its challenges. Issues such as methane leakage during extraction and transportation pose environmental risks, while concerns about finite reserves raise questions about the long-term sustainability of natural gas as an energy source. However, ongoing research and development efforts are focused on addressing these challenges and finding innovative solutions to ensure the continued viability of natural gas as a primary energy source.

1. Residential Home heating systems, water heaters, and gas stoves all utilize gas regulators to maintain safe and efficient operation.

Benefits of Using Pressure Regulating Devices

What is a Pneumatic Control Valve?

To conclude, electric heaters present an efficient, safe, and versatile option for home heating. With their energy-saving features and environmental benefits, they are becoming an increasingly popular choice among homeowners. As technology continues to evolve, electric heaters are likely to become even more efficient and sustainable, making them a viable solution for heating in the modern world. By understanding the various types of electric heaters available and their operational features, consumers can make informed decisions that best suit their heating needs while also being mindful of energy consumption and environmental impact.

Understanding Pressure Pipes

As the gas pressure in the reducer rises, it lifts the diaphragm against the spring force until it reaches a set point. Once the set point is achieved, the diaphragm adjusts to maintain this pressure by allowing extra gas to flow through the outlet while simultaneously limiting the inlet flow. In this way, the reducer stabilizes the output pressure, ensuring that the downstream equipment receives gas at a consistent and safe level.

Choosing the Right Gas Pressure Regulating Valve

At its core, a safety valve is engineered to automatically release excess pressure from a system when it exceeds a set threshold. This mechanism prevents catastrophic failures such as explosions or equipment damage, which could result in injuries, fatalities, and significant financial losses. The design of safety valves varies depending on their application, but they all share the same fundamental objective to ensure safety through pressure regulation.

The breather valve is designed to automatically open when the pressure inside a system exceeds a certain set point. This ensures that the equipment is not damaged or compromised due to excessive pressure. In addition to releasing pressure, the breather valve also prevents the formation of a vacuum by allowing air to enter the system when needed.

The mobility of skid-mounted equipment is a significant advantage over traditional fixed systems. These skids are built to be moved easily from one site to another, making them ideal for operations that require frequent relocation. This is particularly beneficial in projects that demand flexibility and quick adaptation to changing circumstances, such as mining or construction projects. The ability to transport equipment easily reduces downtime and enhances overall productivity, allowing companies to respond swiftly to operational demands.

2. Spherical Vessels Spherical pressure vessels provide a unique solution by minimizing stress concentrations due to their geometric shape. This design is particularly beneficial for storing gases at very high pressures. Although they occupy more space, their strength and efficiency in handling pressure make them suitable for specific applications.

Understanding Pressure Reducing Valves A Key Component in Fluid Control Systems

Closing valves come in several varieties, each designed for specific applications and operating conditions. The most common types include

In conclusion, the concept of NG transcends mere technological advancement; it embodies a holistic transformation of our society. By embracing Next Generation technologies, we can create a more connected, efficient, and inclusive world. The potential for positive change is immense, but it requires a collective effort to address the challenges that accompany such rapid evolution. As we stand at the brink of this new era, the choices we make today will shape the future, guiding us toward a realm where the possibilities are limitless. Embracing NG is not just about innovation; it is about envisioning a better tomorrow for all.

3. Pressure Control Valves Safety is paramount in pneumatic systems, and pressure control valves play a significant role in maintaining the system's pressure. These valves help prevent over-pressurization, which can lead to equipment failure or dangerous situations.

What are Distribution Stations?

In conclusion, natural gas filters are an indispensable part of the natural gas industry, playing a crucial role in safeguarding equipment, ensuring compliance with regulations, and enhancing the overall efficiency and sustainability of the energy supply. As the world continues to transition towards cleaner energy sources, the importance of advanced gas filtration technologies will only grow. Investing in high-quality filtration systems is not just a matter of operational efficiency; it is a critical step towards a sustainable energy future.

2. Efficiency Gas pressure reduction stations play an essential role in maintaining the efficiency of the gas distribution network. By managing pressure levels effectively, they ensure that gas can flow smoothly into distribution networks without causing strain on pipelines. This efficiency lowers operational costs and helps prevent gas loss due to leaks.

In the world of machinery and equipment, the integration of various tools and devices onto a slider is a trending practice that enhances functionality, mobility, and efficiency. The concept of equipment mounted on a slider refers to the strategic placement of devices on a mobile platform, allowing for ease of movement and versatility in usage. This article explores the various aspects of this innovative approach, highlighting its benefits, applications, and considerations.

How Cyclone Separators Work

How Gas Pressure Reducers Work

In recent years, Al-Madina Gateway Station has emerged as a significant landmark in the realm of modern transportation, serving as a vital hub for travelers and a symbol of progress for the city of Medina. With its unique design and strategic location, the station is not just a transportation facility but a reflection of the city’s cultural heritage and its commitment to embracing the future.

One of the primary functions of natural gas valves is to ensure safety in gas handling and distribution. Natural gas is flammable, and any leaks or uncontrolled flow can lead to hazardous situations. Valves equipped with safety features, such as emergency shutdown options, are essential in preventing accidents. For example, in the event of a pipeline rupture, automatic shut-off valves can quickly halt the gas flow, minimizing the risk of explosions or fires.

Conclusion

At its core, a pressure reduction station consists of equipment designed to reduce the high-pressure gas received from transmission pipelines or storage facilities. The gas supplied through these high-pressure lines often exceeds safe operating levels for residential and commercial applications. This is where the PRS comes into play, transforming high-pressure gas into a stable pressure suitable for downstream distribution.

1. Directional Control Valves These valves determine the path that the compressed air takes. They can switch the air's direction, allowing for the operation of actuators in various positions. Common configurations include 2/2, 3/2, and 5/2 valves, indicating the number of ports and positions.

A pressure reducer is a mechanical device designed to decrease the pressure of gas or liquid from a high level to a lower, more manageable level. It can regulate the flow and maintain a stable output pressure, regardless of fluctuations in the input pressure. This function is essential in many industries, including healthcare, manufacturing, and energy, where precise pressure control is necessary.

In conclusion, safety valves are a cornerstone of industrial safety, providing an essential function in pressure regulation to prevent accidents and protect lives. Their significance spans across various industries, underscoring the universal need for effective safety mechanisms. As technology continues to evolve, the role of safety valves will likely become even more critical, ensuring that industries can operate safely amidst evolving challenges and risks. Therefore, investing in quality safety valves and adhering to maintenance protocols is not just good practice; it is a vital requirement for the sustainability and safety of industrial operations.

As technology advances, the future of pressure relief valves stands to benefit from innovations in materials and automation. New materials may provide improved corrosion resistance and durability, extending the lifespan of the valves. Furthermore, integrating smart technologies can enhance monitoring and control, allowing for real-time assessments of the valve’s performance and conditions within the system.

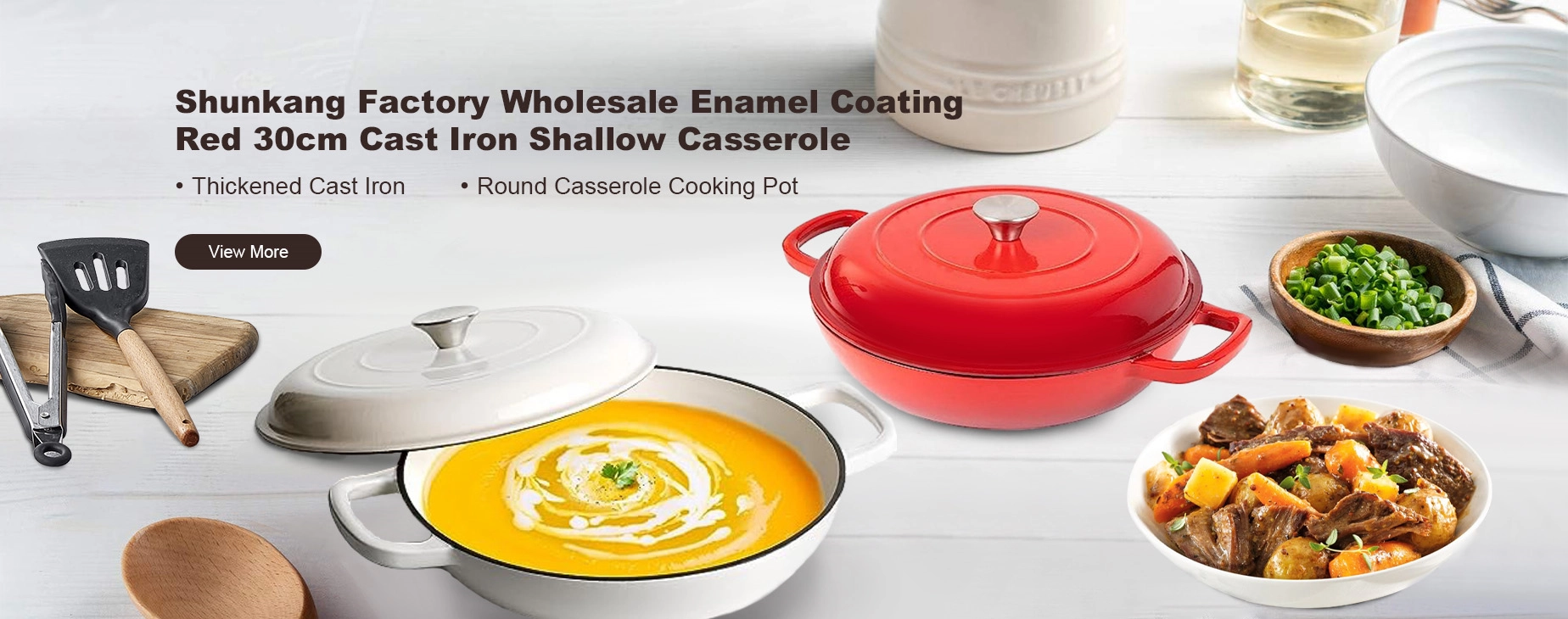

They draped these cooking containers above trench walls so they could enjoy warm meals even without access to ovens or stoves.

When grilling with a cast iron griddle plate it's important to preheat the griddle onto the grill before adding food. This keeps the pan hot enough to create nice grill marks and caramelization. Make sure to brush the baking sheet with a light layer of oil to prevent sticking and aid in the baking process. Once the cast iron griddle plate is hot, place the food on a baking sheet and let it cook to perfection.

Copper core frying pans have a copper exterior for excellent heat conductivity and a stainless steel interior for durability and easy cleaning. They are ideal for cooking high-heat dishes, sauces, and eggs. However, they are expensive and prone to discolouration with prolonged use.

Copper core frying pans have a copper exterior for excellent heat conductivity and a stainless steel interior for durability and easy cleaning. They are ideal for cooking high-heat dishes, sauces, and eggs. However, they are expensive and prone to discolouration with prolonged use.

The major difference between stainless steel and non-stick cookware is the material used for the bottom of the pan. This non-stick material, as discussed earlier, is easy to clean but requires more frequent and gentle cleaning.

On the other hand, stainless steel pans can handle rough cooking and cleaning while requiring very little maintenance thanks to their sturdy nature.

This means that they can be used on both stovetops and ovens, making them incredibly versatile This means that they can be used on both stovetops and ovens, making them incredibly versatile

This means that they can be used on both stovetops and ovens, making them incredibly versatile This means that they can be used on both stovetops and ovens, making them incredibly versatile cast iron frying pan price. Additionally, cast iron pans are relatively easy to care for, requiring only a simple seasoning process to maintain their non-stick properties.

cast iron frying pan price. Additionally, cast iron pans are relatively easy to care for, requiring only a simple seasoning process to maintain their non-stick properties. With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions

With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions griddle grill cast iron.

griddle grill cast iron.There are a variety of non-stick coatings a frying pan can have, such as a standard PTFE non-stick coating to manufacturer-specific coatings. Read on to learn more about the different types of non-stick coatings a pan can have, ranging from good to best.

It is also a good idea to place the griddle on a hot stove or in the oven for a few minutes to ensure that all moisture is evaporated It is also a good idea to place the griddle on a hot stove or in the oven for a few minutes to ensure that all moisture is evaporated

It is also a good idea to place the griddle on a hot stove or in the oven for a few minutes to ensure that all moisture is evaporated It is also a good idea to place the griddle on a hot stove or in the oven for a few minutes to ensure that all moisture is evaporated washing cast iron griddle. Once the griddle is dry, apply a thin layer of vegetable oil or shortening to the surface to re-season it. This will help to maintain the non-stick properties of the griddle and prevent rusting.

washing cast iron griddle. Once the griddle is dry, apply a thin layer of vegetable oil or shortening to the surface to re-season it. This will help to maintain the non-stick properties of the griddle and prevent rusting.

They draped these cooking containers above trench walls so they could enjoy warm meals even without access to ovens or stoves.

Though stainless steel started in the 1930s and continued after World War II, stainless frying pans were only mass-marketed in the 1950s. Companies concentrating on cookware produced the first stainless steel frying pans.

Ceramic frying pans are made from a non-toxic, non-reactive material that is known for its non-stick properties and fast heating capabilities. They are ideal for cooking delicate dishes and reducing the amount of oil needed for cooking. However, they are prone to scratching and may not be suitable for high-heat cooking.

Ceramic frying pans are made from a non-toxic, non-reactive material that is known for its non-stick properties and fast heating capabilities. They are ideal for cooking delicate dishes and reducing the amount of oil needed for cooking. However, they are prone to scratching and may not be suitable for high-heat cooking.

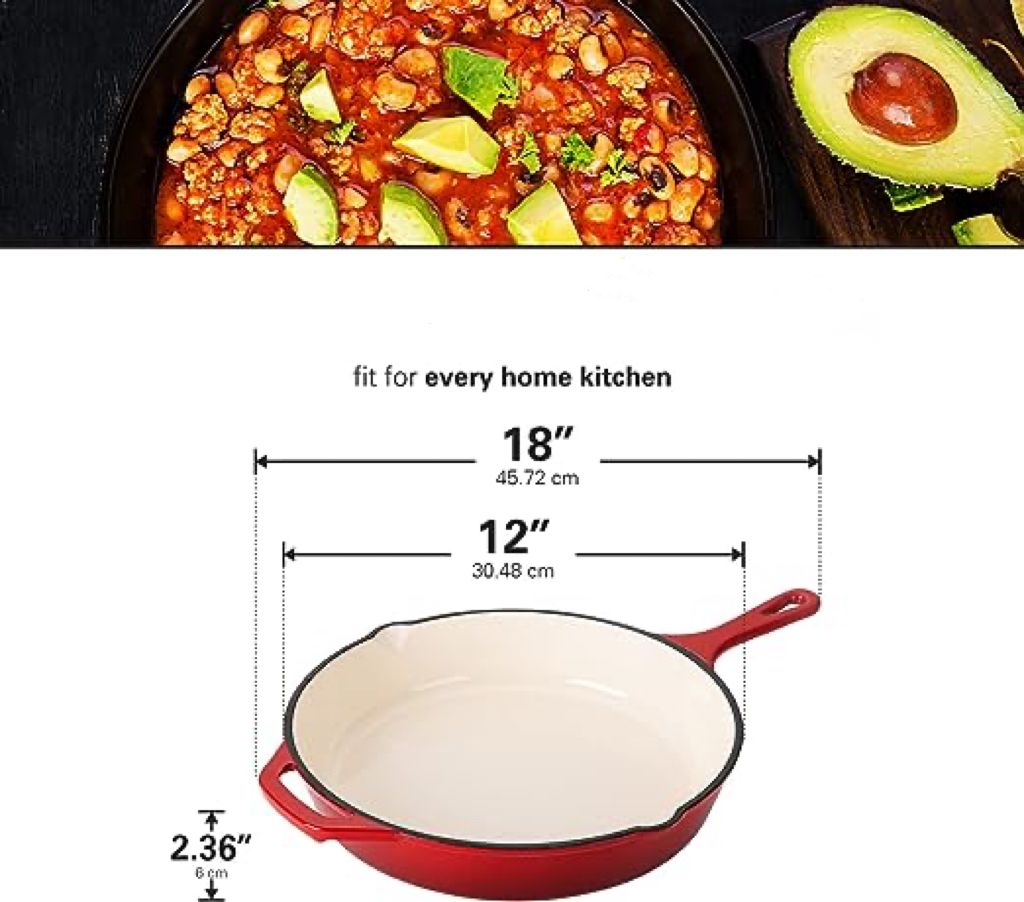

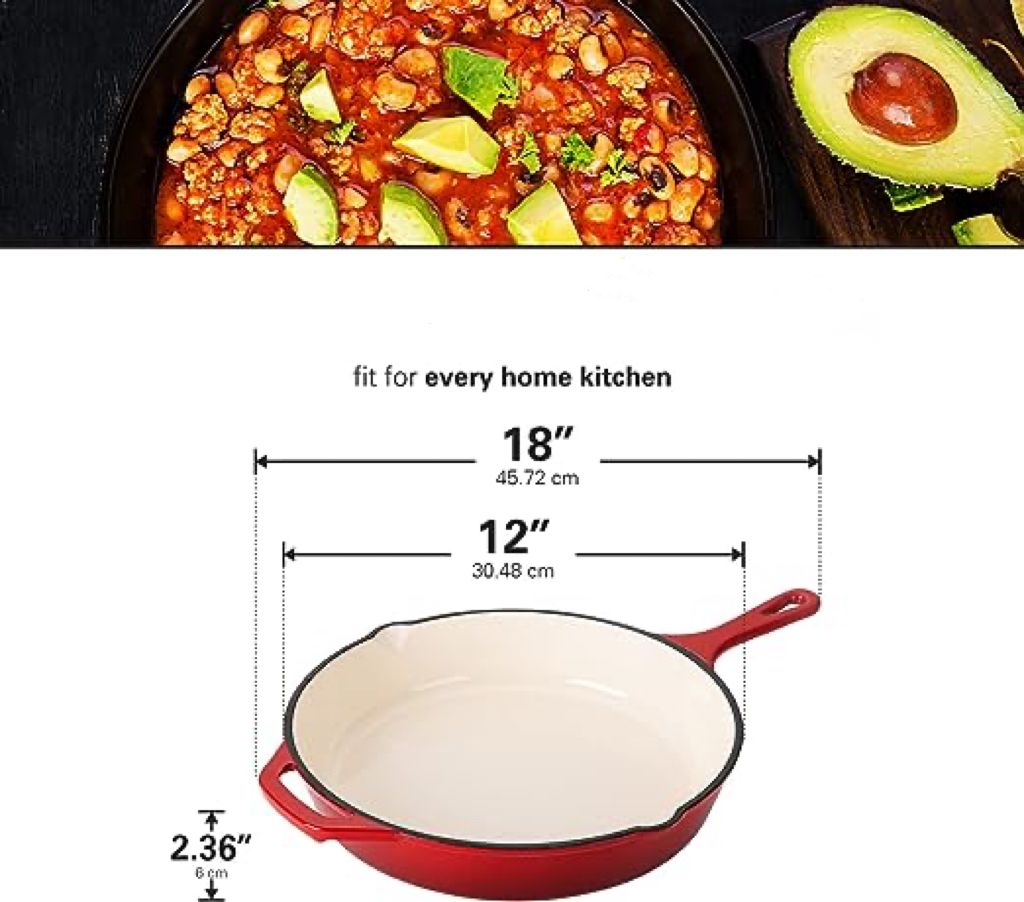

Skillet